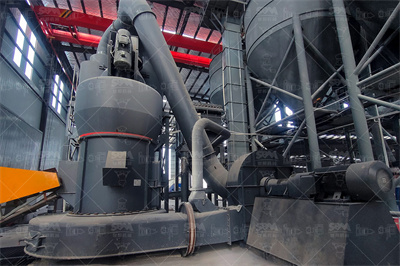

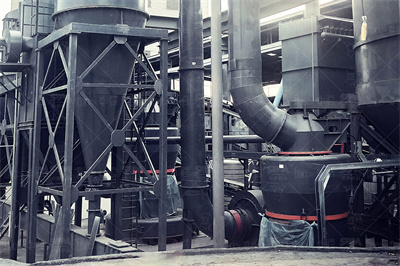

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

中国石化拥有普光气田、元坝气田以及众多加工高硫原油的炼油厂,这些炼油厂在加工原油的过程中产生大量的硫磺副产品。 通过先进的脱硫技术,这些副产品被有效回收和 .

工业硫磺为易燃固体。此外,空气中含有一定浓度硫磺粉尘时不仅遇火会发生爆炸,而且硫磺粉尘也很易带静电产生火花导致爆炸(硫磺粉尘爆炸下限为/m 3),继而燃烧引发火灾。按固体火灾危险性分类硫磺属于乙类,硫磺回收和成型装置属于火灾危险性乙类装置。

工业硫磺用于制造硫酸、染料和橡胶制品,也用于医药、农药等工业部门。 袋装硫磺成垛堆放,堆垛间应留有不小于交通道;不允许放置在上、下水管道及取暖设备近 .

食品级硫磺与工业硫磺两者的区别主要在于其有害物质含量高低不同。 工业硫磺由于含有较多的重金属,如砷等,对人体的危害尤其严重。 砷会蓄积于骨质疏松部、肝、肾、 .

食品级硫磺,亦即作为食品添加剂的硫磺,是通过工业硫磺的加工、处理和提纯过程制得的。 作为漂白剂和防腐剂,食品级硫磺被允许用于六类食品的加工:水果干、蜜饯凉果、干制蔬菜、经过表面处理的鲜食用菌和藻类、食糖以及魔芋粉。

原料气(酸性气体)经过燃料转化,使硫化氢氧化成硫磺,未反应的原料气再重新进行氧化,从捕集器分离出的液体硫,经造粒成型、包装出厂。 展开 硫磺主要用来生产硫酸、染料、烟花爆竹及橡胶制品,还可用于军工、医药、农药等部门。食品硫磺在食品工业中可用来防腐、杀虫、漂白、熏染等,还可用于淀粉工业软化玉米及其它原料用。采用本 . 展开 硫磺是一种黄色固体,分结晶形和无定型两种。熔点~℃,沸点℃,不溶于水,稍溶于酒精和醚类,易溶于二氧化碳、四氯化碳和苯。该品属于二级易燃物,自然 . 展开

硫磺是如何生产的?在经过炼油的主要生产车间后(例如常减压、催化裂化、加氢裂化、延迟焦化等),会分离出石油中的硫,以含硫污水的形式输送至硫磺回收处理车间。硫 .

摘要:硫磺的应用十分广泛,在橡胶、建材、化工、农业、医药、化肥等领域都有所应用,是一种非常重要的化工原料。 随着我国技术的快速发展,我国硫磺产品也在随之增 .

化工产品:硫磺用于生产多种化工产品,如硫化碱、硫化氢、硫代硫酸钠等,广泛应用于染料、医药和农药制造中。 金属冶炼:硫磺在金属冶炼过程中用于脱硫,帮助提高金 .

由于此网站的设置,我们无法提供该页面的具体描述。

硫磺作为一种重要的化工品生产原料,其制造方法对于提高产量、降低成本、提高产品质量等方面具有重要意义。 本文介绍了天然硫磺的开采和加工方法以及人工合成硫磺的 .

由于此网站的设置,我们无法提供该页面的具体描述。

GB食品安全国家标准食品添加剂硫磺本标准代替GB3150—1999《食品添加剂硫磺》。 本标准与GB3150—1999的主要技术差异如下:——增加了硫化物指标及试验方法;——增加了重量法测定有机物含量;——增加了二乙基二硫代氨基甲酸银分光光度法测定砷含 .

硫磺是一种基本化工原料,国内75%的硫磺都被用来生成硫酸,而硫酸又是生产磷肥的重要化工原料。硫磺的下游消费主要是磷复肥、硫酸、钛白粉、染料中间体及食品等领 .

现行的《食品安全国家标准 食品添加剂使用标准 GB 》规定,食品级硫磺作为漂白剂、防腐剂,可用于水果干类、蜜饯凉果、干制蔬菜、经表面处理的鲜食用菌和藻类、食糖和魔芋粉等食品的加工,但只限用于熏蒸,最大使用量有明确要求,并以工业级

食品添加剂硫磺可广泛用于食糖、淀粉、医药、酿酒、食品加工等方面, 具有杀菌、漂白、入药等用途, 其标准号为 StandardNo:GB 3150―2010。本标准的检验方法所用试剂和水在没有注明其他要求时,均指 分析纯试剂 和GB/T 6682—2008 中规定的三级水。 ...

对于涉嫌违法使用工业硫磺熏制食品的加工 户,一经查实,将移送司法机关依法追究刑事责任。 2019年11月青海省海西蒙古族藏族自治州出台施行了高于国标的地方标准,为的是打造更好的青海品牌。而甘肃,也是多年多次地出台培育地方枸杞 ...

用燃烧硫磺熏蔬菜或用亚硫酸及其盐类配制成一定浓度的水溶液来浸渍蔬菜的措施,称为硫处理。许多供作干制的蔬菜如甘蓝、竹笋、黄花菜、马铃薯等经过切分、热烫后,一般都要进行硫处理。蔬菜原料通常在采收后要进行硫处理,其主要目的是防止原料在加工过程中及加工品贮藏期间的褐 .

由于此网站的设置,我们无法提供该页面的具体描述。

9月1日,央视财经曝光了甘肃省靖远县"硫超标"枸杞加工黑幕。 记者来到甘肃省靖远县,这里的枸杞种植面积大约有28万亩 ...

硫磺在食品加工中, 可以起到去色增白、防腐的作用。记者梳理近年来曝光的硫磺加工食品违法事件发现,违法行为主要分为三大类:使用工业硫磺进行食品加工、二氧化硫残留量超标,以及对在允许使用硫磺加工的食品范围之外的食品进行硫磺加工。

有网友于9月11日在国家市场监督管理总局网站公众留言系统咨询关于硫磺加工成硫磺粉是否需要办理《全国工业品生产许可证》的问题,9月19日 ...