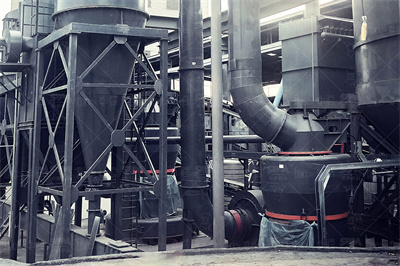

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

黑钨矿选矿生产线设备配置 红星机器对黑钨矿成分详细分析,并结合其实际应用情况,设计了经济效能高的选矿生产线,配置了设备方案,有助于提高企业经济效益,推动该矿产资源的综合利用。接下来对黑钨矿选矿生产线主要设备简要介绍。1、黑钨矿破碎设备

阿里巴巴Φ1830*7000全封闭式棒磨机 钨矿连续作业设备 防尘防腐工艺,球磨机,这里云集了众多的供应商,采购商,制造商。 ...,东北亚,中东,有可授权的自有品牌:是,是否跨境出口专供 .

混凝土网为您提供广东清远项目,信息如下:台湾水泥英德厂招标公告 本案「振动磨磨盘材质碳化钨ø160mm」将依下列信息进行招标工作, 首页 混凝土价格 水泥价格 砂石骨料价格 混凝土指数 项目信息 资讯中心 商混站

行星式球磨机 (Planetary activator)是混合、细磨、小样制备、纳米材料分散、新产品研制和小批量生产高新技术材料的必备装置。 该产品体积小、功能全、效率高是科研单位、高等院校、企业实验室获取微颗粒研究试样(每次实验可同时获得四个样品)的理想设备,配用真空球磨罐,可在 .

2760球磨机作为一种常用的磨矿设备,它的筒体直径米,筒体长度为6米。2760球磨机在矿石粉磨过程中发挥着重要作用。了解和优化2760球磨机的技术参数对于提高磨矿效果、降低能耗和提升生产效率至关重要。

白钨矿球磨分级生产线简介 白钨矿球磨分级生产线是对白钨矿进行研磨加工的专属设备,是埃尔派粉体依据白钨矿的性质加工而成的,具有耗能低、产量高、耐用性强、密封性好等特点,不仅有效简化了下一道工序的生产,而且为用户的生产带来较高的盈利。

国家计委关于放开和下放部分商品和服务价格的通知(二)由于供求情况变化和取消指令性计划,实际工作中未再审批但尚未明令放开 ... 石,磷精矿,硼矿石,硫酸,轮胎,矿用装载机,矿用挖掘设备,大型堆取料机,大型破碎粉磨设备 ...

在进行钨矿选别之前,要经过破碎和磨矿阶段,白钨矿球磨机是磨矿阶段非常重要的设备,球磨机的合理使用可有效提升白钨矿物料的加工利用率。白钨矿球磨机的价格也是备受客户关注的问题,那么哪些因素会影响它的价格呢?下面我们做具体的分析。

了解磨机设备的选型方案及设备价格,需要掌握项目的生产需求,客户所需要的粉磨细度、产能、设备安装区域等信息都不同,为客户提供专业的技术支持,并且提供量身定制服务,定制出合理的磨机价格。 金属钨实验型针盘磨从哪个厂家采购*放心?

广州儒佳机电设备有限公司是一家化工分散研磨设备生产厂家,提供一体化单元投料分散研磨IDS系统,包括砂磨机、分散机、无尘粉体投料机等优质设备,涂料、油墨、喷墨墨水、农药、陶瓷、 .

价格放开后,各地要加强对上述商品和服务价格的监测,在运行中出现的矛盾和问题,请及时报告我委。 二、蚕茧、糖料收购价格和中央直属热电厂供热出厂价格下放省级价格主管部门管理。国家级特殊游览参观点门票价格去年已下放由省级价格主管部门管理。

阿里巴巴立磨工艺目数600目 超细磨粉设备 LUM超细立磨价格 厂家直销,粉碎机,这里云集了众多的供应商,采购商,制造商。这是立磨工艺目数600目 超细磨粉设备 LUM超细立磨价格 厂家直销的详细页面。订货号:002004,品牌:黎明重工,货号:002004,型号:LUM,适用物料:矿石、煤炭等,应用领域:非金属矿 ...

棒磨机设备是重要的粉磨设备,其规格表示一般为直径D×长度L,其磨矿介质为钢棒,其按排料分类可分为溢流型棒磨机和周边排料型,筒体形状为L=(~)D。 棒磨机设备的工作原理:棒磨机圆筒受到电机和传动装置的驱动做回转运动。在摩擦力的作用下,磨矿介质钢棒被筒体的内壁衬板带动,并升 ...

球磨机是是磨矿车间的必要设备,也是整个选矿流程中耗能较大的选矿设备。在设备选型时,我们先要了解的便是球磨机的型号规格,根据跟选矿厂是实际情况选择适合的球磨机类型及适合的型号规格,对选矿厂来说,是保障磨矿效率的关键。

通过以上分析,要求客户在购买粉碎机时进行实地考察,从设备质量、工厂规模和售后服务等方面不盲目考虑价格,以找到合适的设备。 埃尔派秉承"履行社会责任,做优秀企业公民"的理念,每销售一台设备都将捐出1000元公益基金,用于救助山区贫困失学儿童和困难职工 .

钨矿效能高球磨机的价格并没有一个固定值,主要是因为其受许多因素主观及客观因素影响,比如设备质量、厂家性质、型号大小、钢材价格变动等,下面一起来看详细分析: .

超细磨粉机超细微粉磨价格立式磨机超细磨厂家河南兴邦重工钨矿选矿设备锰矿选矿设备锑矿选矿设备赤铁矿选矿设备磁铁矿选矿设备铬矿适用物料超细磨粉机是在雷蒙磨的基础上研制的一种超细粉磨机,主要用于冶金建材

球磨机适用于粉磨各种矿石及其它物料,被广泛用于选矿,建材及化工等行业,可分为干式和湿式两种磨矿方式。 根据排矿方式不同,可分格子型和溢流型两种。

焦炭制球机厂天鑫为您提供天鑫实验室振动盘式粉碎研磨机碳化钨 | 氧化锆 | 玛瑙 | 不锈钢磨盘实验室振动盘式粉碎研磨机的参数、价格、型号、原理等信息,其它煤炭行业碳化钨 | 氧化锆 | 玛瑙 | 不锈钢磨盘实验室振动盘式粉碎研磨机,产地河南,品牌为天鑫,焦炭制球机厂天鑫客服电话:,售前 ...

新乡市长城机械有限公司是一家拥有50余年水泥粉磨设备生产经验的高新技术企业,生产的产品主要包括立磨机、球磨机、回转窑、水泥生产线、矿粉生产线、粉磨机配件、铸钢件等。黑钨矿选矿生产线设备配置及工艺流程机器 3、黑钨矿浮选设备–黑钨矿浮选机

5、长期投资赣州水泥粉磨厂为钨矿全资公司,该投资按成本法核算,审计中根据水泥。白钨矿球磨机球磨机闭路粉磨的优缺点价格,厂家,图片,球磨机, 闭路粉磨的缺点:流程复杂、设备多、投资大、厂房高、操作麻烦、人员多、维护工作量大,系统设备的运转率较低。

钨矿深加工设备钨 矿磨粉机推荐 磨机名称:HLM立式磨粉机 成品细度:22180μm 生产能力:5200t/h ... 电耗低、产品细度易于调节、占地面积小、噪音低、扬尘小,是设计结构科学,工艺高超,粉磨效率高的干法磨机设备 。经过多年的发展,桂林鸿 ...

通过引进先进的生产工艺实现技术创新,进一步满足了市场的需求,而且在服务上同样非常完善,组建有专业的方案设计团队,运用丰富的经验和专业的机械知识,为每一个客户提供量身定制服务,匹配出合理的选型配置方案,提供理想的生产设备价格。 碳化钨

仪器信息网粉磨设备专题为您提供2024年最新粉磨设备价格报价、厂家品牌的相关信息, 包括粉磨设备参数、型号等,不管是国产,还是进口品牌的粉磨设备您都可以在这里找到。

粉磨钨矿的设备 选锌设备 选铅锌设备如何有序实施破碎工作选铅锌设备又称选铅设备或选锌设备,在选铅锌设备之中实施每道工序都是讲究循序渐进的,为此选铅设备、浮选设备、选锌设备等都在操作方面有一定的次序的,比如鄂式破碎机产品,其单单开始作业需要经历简单却方方面面的核 .