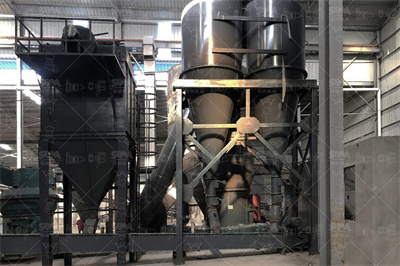

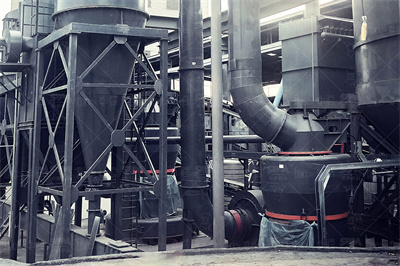

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

阿里巴巴中州机械4r雷蒙磨 326型石灰石磨粉机 重晶石雷蒙磨机厂家优惠价,粉碎机,这里云集了众多的供应商,采购商,制造商。这是中州机械4r雷蒙磨 326型石灰石磨粉机 重晶石雷蒙磨机厂家优惠价的详细页面。订货号:3216,品牌:中州,货号:2024,型号:4r3216型,适用物料:白灰、石灰石、矿石、页岩 ...

阿里巴巴为您找到503个今日最新的4R3216型雷蒙磨粉机价格,4R3216型雷蒙磨粉机批发价格等行情走势,您还可以找石灰石雷蒙磨粉机,雷蒙式磨粉机,1410雷蒙磨粉机,雷蒙磨粉机 小型,5r雷蒙磨粉机,雷蒙磨粉机磨辊,雷蒙磨粉机1510,pvc磨粉机,雷蒙磨粉机2615,大型雷蒙磨粉机市场价格、批发价格等相关产品的价格 ...

广西化工磨粉机 雷蒙磨机 2715化工原料研磨机 出粉细产能高中州 广西桂林雷蒙磨生产厂家 加工碳酸钙粉的设备 煤粉加工设备 【源厂直销】广西桂林雷蒙机 洒石粉机械设备 雷磨机价格 广西雷磨机 4r3216型细粉雷蒙机 磨石灰石磨粉机

雷蒙磨4r3216型产品_郑州曙光重型机器有限公司 2017年7月24日雷蒙磨4r3216型产品 ppc型气箱脉冲除尘器 新型雷蒙磨分析器的主要特点和功能 上一篇:磨粉机行业朝着节能环保化发展 下一篇:新品96袋脉冲除尘器生产现...

河南中州 雷蒙磨粉机配件 4r3216型雷蒙磨粉机磨环 ... 【雷蒙磨粉机】价格|批发|厂家_顺企网 顺企网为您找到"雷蒙磨粉机的工作原理、应用范围、桂矿牌雷蒙磨粉机环辊磨超细磨粉机、膨润土磨粉机工作原理,hc系列雷蒙磨粉机型号、优质液压雷蒙磨粉机 ...

4R3216保守值400700小时雷蒙磨粉机 高产量设备. 一、简介:R型摆式磨粉机又称为雷蒙机,广泛应用于建材、化工、造纸、医药、食品、能源等行业。 适用于粉磨硬度莫氏七级以下,湿 .

雷蒙磨粉机R型摆式磨粉机,原名悬辊式磨粉机,又称为雷蒙磨、悬辊式盘磨机、环滚研磨机、摆轮式研磨机,是一种以环、辊碾磨结合气流筛选、气力输送形式的制粉设备。具有干法连续制粉,粒度分布集中、细度连续可调、

【环保型雷蒙磨生产厂家,4r3216雷蒙磨粉机,雷蒙磨价格】价格_厂家... 饲料铡草粉碎机 农用切草铡草机 秸秆揉丝机 铡草揉丝一体机 ¥ 查看更多 郑州振恒机械设备有限公司 环保型雷蒙磨生产厂家,4r3216雷蒙磨粉机...

阿里巴巴为您找到290个今日最新的4R3216型雷蒙磨价格,4R3216型雷蒙磨批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。

搜好货网()为您提供各种4r3216雷蒙磨的供求信息价格,4r3216雷蒙磨资讯,4r3216雷蒙磨图片,4r3216雷蒙磨厂家等,查找更多的4r3216雷蒙磨产品信息和供应商请上搜好货网。

阿里巴巴为您找到1056条3216雷蒙磨产品的详细参数,实时报价,价格行情,优质批发/ ... 4r3216型欧版雷蒙磨粉机 大型高压水镁石磨粉机 碳化硅雷蒙机 郑州慧诚机械设备有限公司 7年 月均发货速度 ...

阿里巴巴为您找到115个今日最新的广西桂林雷蒙磨机价格,广西桂林雷蒙磨机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关广西桂林雷蒙磨机供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。

阿里巴巴为您找到308条供应4r3216型雷蒙磨粉机产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息 ... 高压新式雷蒙磨粉机 雷蒙磨图片 3216雷蒙磨技术参数及报价 ...

雷蒙磨广泛用于建材农业、金化、造纸、医药、食品、能源等作业磨碎莫氏硬度7级、湿度6%以下,若采用热风,可磨碎湿度达10%―12%的非易燃易爆物料,如土类:粘土 .

阿里巴巴为您找到93条广西雷蒙磨机产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息 ... 广西桂林雷蒙磨生产厂家 加工碳酸钙粉的设备 煤粉加工设备 世邦工业科技集团股份有限公司 ...

阿里巴巴为您找到403条4r3216型雷蒙磨产品的详细参数,实时报价,价格行情,优质批发/ 供应等信息 ... 雷蒙磨价格,雷蒙磨型号,开泰雷蒙磨多少钱一套? 河南开泰环保科技有限公司 ...

4r3216雷蒙磨品牌/图片/价格 4r3216雷蒙磨品牌精选大全,品质商家,实力商家,进口商家,微商微店一件代发,阿里巴巴为您找到660个有实力的4r3216雷蒙磨品牌厂家,还包括价格,高 .

活性炭雷蒙磨粉机生产线配置方式多_桂林也有升级版雷蒙磨粉机hc摆式磨粉机作主机配置双旋风。r型4r3216活性炭雷蒙磨粉机配套生产线r型活性炭。系统的动力装置可采用减速机传动和双传动装置两种方式。 。1700磨粉机,雷蒙磨工作原理图磨粉机纵摆式磨粉机

在使用磨粉机的时候,一般新的产品它们不会有一些问题存在的,4r雷蒙磨,但使用的时间长一些的时候,4r雷蒙磨哪家好,它们的会出现一些不好的使用的问题,对于磨粉机在提供多种型号的【4R3216雷蒙磨价格多少,厂家在哪?】,厂家直接供货价格优势明显,河南重工雷蒙

产品名称:4r3216雷蒙磨粉机=雷蒙磨价格维科磨粉机。郑州维科重工机械专业生产销售磨粉机。。型雷蒙磨粉机又叫雷蒙磨机、雷磨机、雷蒙磨粉机,广泛应用于冶金、建材、化工、矿山等领报价获取4r雷蒙磨4r3216雷蒙机耐磨性磨辊磨环配件提供4r雷蒙磨4r。

阿里巴巴为您找到69个今日最新的广西桂林雷蒙磨机价格,广西桂林雷蒙磨机批发价格等行情走势,您还可以找市场价格、批发价格等相关产品的价格信息。阿里巴巴也提供相关广西桂林雷蒙磨机供应商的简介,主营产品,图片,销量等全方位信息,为您订购产品提供全方位的价格参考。