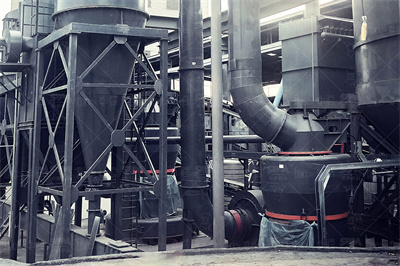

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

报告以图表呈现了2024年中国超声和气压弹道碎石术市场上排行前三品牌市占率与排行前五品牌市占率,并重点分析了各主要企业超声和气压弹道碎石术销售量、销售收入、 .

湾沚区总医院超声气压弹道碎石清石系统采购项目中标(成交)结果公告 一、项目编号 : WH12CG2022HW6125 二、项目名称 :湾沚区总医院超声气压弹道碎石清石系统 .

韶关市第一人民医院腔内碎石机(超声弹道碎石 系统)、泌尿外科超高清摄像系统采购项目中标结果公告 日期: ... 品牌 规格型号 数量(单位) 单价(元) 总价(元) .

1.品名:超声气压弹道碎石系统 2.品牌:北京汇福康 3.产品外观图:.lakhmedical 汇福康产品信息、数据及外观图二 注册号国食药监械(准)字2011第号 产品名称超声 .

5.膀胱弹道碎石镜 PPSII参考信息中涉的配件品牌生产批次不同生产厂家存在更新或替换的可能性,具体实物为准。 官方微信 价格说明 膀胱弹道碎石镜 PPSII 在寰熙网如展示标价的,具体的 .

二、项目名称:腔内气压弹道碎石 机(第三次) 三、中标(成交)信息 供应商名称:杭州康茂医疗器械有限公司 ... 供应商名称 货物名称 货物品牌 货物型号 货物数量 货物 .

中国气压弹道碎石机行业市场前景预测及投资价值评估分析报告博研咨询市场调研在线网北京博研智尚信息咨询 ... 以迈瑞医疗为例,该公司2024年推出的最新款气压弹道碎石 .

中国超声和气压弹道碎石术行业主要企业有Advin Health Care, Novamedtek, Advanced Health Care Resources, EMD Medical, Inceler Medikal, Apex Meditech, EMS .

阿里巴巴为您找到超过40条弹道碎石产品的详细参数,实时报价,价格行情,优质批发/ 供应等货源信息,还能为您找到弹道碎石在淘宝、天猫、京东、亚马逊的同款货源,您还可以找等产品 .

瑞士EMS第四代超声波弹道碎石机, 瑞士第四代EMS超声弹道碎石 目前国际上*先进、*理想、创伤*小、效果*好的新设备 是国际上唯一一种能在碎石的同时进行清石治疗的高 .

钬激光优点:钬激光碎石与目前常用的体外冲击波碎石、气压弹道碎石 进口臭氧治疗仪品牌 医用臭氧治疗仪品牌 疼痛臭氧治疗 医用臭氧治疗仪欧恩兰臭氧 气压弹道碎石机_泌尿外科_按科室 .

一、项目编号: ZJZCFSDZ(2022)公字第0006号 二、项目名称: 镇江市中西医结合医院超声气压弹道碎石系统、钬激光治疗系统项目 三、中标信息 供应商名称: 嘉沐尼宝( .

本公司生产销售气压弹道碎石手柄 碎石手柄,提供气压弹道碎石手柄专业参数,气压弹道碎石手柄价格,市场行情,优质商品批发,供应厂家等信息.气压弹道碎石手柄 气压弹道碎石 .

安和超声气压弹道碎石系统CQS01是一款专为泌尿结石治疗设计的先进医疗设备。 该系统以其广泛的适用范围和多样化的碎石方式,为泌尿科医生提供了一个有效、准确的治疗平台。 CQS .

从临床角度对比分析泌尿外科器械国内外品牌差异. 2015年08月06日 09:54:18 医保信息编辑 中国医药经贸

由于弹道碎石不产热,因此不会引起尿路上皮的热损伤。 弹道碎石的另一优势是费用相对便宜,维护成本低。尽管该设备相比EHL贵,但是弹道碎石没有一次性耗材的损耗, .

免费查询更多气压弹道碎石机国产品牌详细参数、实时报价、行情走势、优质商品批发/ 供应信息等,您还可以发布询价信息。 欢迎来到爱采购,百度旗下B2B平台!登录/注 .

气压弹道碎石机行业市场调查报告对气压弹道碎石机行业市场规模、份额、驱动及制约因素进行了深入评估及分析,此外还从气压弹道碎石机行业概况、上下游情况、市场消 .

气压弹道碎石机行业起源于20世纪80年代,初期主要应用于公路、铁路等基础设施建设领域。 经过数十年的发展,截至2023年,行业市场规模已达到数十亿元,年复合增长 .

超声气压弹道碎石机用零件|品牌:EMS|型号:EL219 中空探针 超声气压弹道碎石机用零件|品牌:EMS|型号:FR084 皮带输送机 输送碎石,矿石;东蒙;B=800L=25M;皮带 .