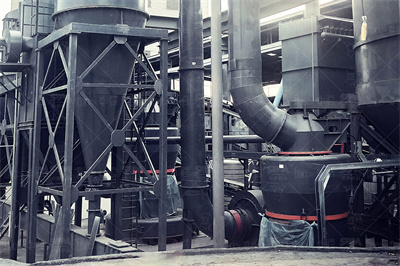

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

最大干容重是 在实验室中得到的最密实状态下的干容重。"容重"与"密度"区别: 容重一般是工程上用的一立方米的重量,即单位容积内物体的重量。而密度应用范围很广, .

该文档介绍了液态粉煤灰的应用技术规程,提供了相关企业标准和备案信息。[END]> <|ipynb_marker|> Markdown**Q: What did you learn from the above?**The assistant .

粉煤灰的容重是多少粉煤灰的容重为吨到区间范围之内略有差异。这是因为不同等级的粉煤灰或者不同类型火力发电厂所产生的粉煤灰可能存在微小的物理特性差异。总 .

炉渣的 组分 靠加入适量的 熔剂 (石灰、石英石、萤石 等)进行调整。 在 冶炼 过程中通过对炉渣组分和性质的控制,能使 脉石 和氧化杂质的 产物 与 熔融 金属或硫顺利分离,脱除金属中的 .

液态粉煤灰配合比设计说明六、确定试验室配合比1)不同用水量材料用量水胶比水泥(kg)粉煤灰(kg)水(kg)备注)不同用水量的强度 .

液态粉煤灰配合比设计说明 一、设计要求及基本资料 本液态粉煤灰配合比7d设计强度为,28d设计强度为,稠度要求为100220mm,拟用于液态粉煤灰回填台背施工 .

由于此网站的设置,我们无法提供该页面的具体描述。

液态粉煤灰配合比设计说明 一、设计要求及基本资料 本液态粉煤灰配合比7d设计强度为, 28d设计强度为,稠度要求为100220mm拟用于液态粉煤灰回填台背施工。 二、 设计 .

粉煤灰的容重一般是多少?/m3。根据华强电子网查询,由于粉煤灰是容重只有/m3、水分<1%的极细粉末,因而粉煤灰具有易流动的物理特性。粉煤灰,就是火力发 .

2 测粉煤灰比重 (3)取干状粉煤灰约300g,在天平上精确称重,并记录G1。 【第一次记在D列中,第二次记在G列中 G1= g g (4)将称好的粉煤灰倒入1000ml的玻璃量筒中。

一立方米粉煤灰等于吨 1、 粉煤灰也是分国标等级的,需要根据他的堆积密度来计算。 一级粉煤灰 /cm3。2、密度:粉煤灰的密度与它的颗粒形状、铁质含量有 .

一立方米粉煤灰等于吨。 粉煤灰也是分国标等级的:一级粉煤灰 /cm^3. 密度:粉煤灰的密度与它的颗粒形状、铁质含量有关,玻璃球含量多,粉煤灰密度 .

粉煤灰的比重计算公式五、结论综上所述,粉煤灰是 一种具有多孔结构、低比重、良好性能的矿物粉末。在建筑行业中,粉煤灰广泛应用于混凝土生产,具有很好的环保和经济效益。同时, .

粉煤灰密度一般多少粉煤灰的密度范围广泛,通常在至克每立方厘米之间,而其堆积密度则在至克每立方厘米。这些物理性质,如密度和堆积密度,是其化 .

由于此网站的设置,我们无法提供该页面的具体描述。

最常用材料容重表石灰煤渣矿渣16石灰煤渣碎石土18水泥石灰稳定砂砾21碎(砾)石21土17土砂粒料改善砂、粘土19砾石21嵌锁级配型基、面层级配碎石22级配砾石22嵌锁级配型基、 .

合格的二级粉煤灰密度应在/cm ³以上。首页 食品检测 农产品检测 消费品检测 全部检测 新闻资讯 联系机构 ... 第三方建筑检测报告办理费用是多少 ?钢材材质检测标准 .

谁知道粉煤灰密度试验方法的国家标准叫什么 2 粉煤灰的ph值实验方法 5 常用粉煤灰密度一般为多少? 粉煤灰的密度是多少? 怎样 .

粉煤灰的密度一般在~吨/立方米之间,具体数值会受到粉煤灰的 物理性质 、颗粒大小、形状等因素的影响。 一般情况下,粉煤灰的密度可以根据实际的试验和测量数 .

三、液态粉煤灰的适用范围 液态粉煤灰最适用于旧路改建中所增构造物的台背回填和已压实的路基增设构造物的台背回填;软基路段构造物的高台背回填;在山区、半山区施工中,由于土质坚 .

粉煤灰是密度是多少?粉煤灰的密度一般在吨/ 立方米左右。具体来说,新产生的粉煤灰比较松散,其密度比较低,通常小于每立方米一吨。但随着堆放时间的增长,特 .

![液态粉煤灰配比 [新版]_百度文库](/2yu1s7f/100.jpg)

液态粉煤灰配比[新版]3、对外加剂的要求①外加剂其性能应能激发粉煤灰早期活性,并具有早强,增调和减水的作用。②细度: ... (稠度控制、施工流动速度是液态水泥粉煤灰能否正常施工的关 .

液态粉煤灰容重的计算公式与常规物质的容重计算公式相同,即: 容重(ρ)= 质量(m)/ 体积(V) 在这个公式中: ρ 表示液态粉煤灰的容重,单位是千克/立方米(kg/m³)或其他相应的单 .

粉煤灰泡沫砌块砌体 ~ 粉煤灰∶电石渣∶废石膏=74∶22∶4 三合土 灰∶砂∶土=1∶1∶9~1∶1∶4 11 隔墙与 墙面 (kN/m 2 ) 双面抹灰板条隔墙 每面抹灰厚 16~24mm,龙骨在内 单面抹 .

1立方粉煤灰等于多少吨一立方米粉煤灰等于吨粉煤灰也是分国标等级的,需要根据他的堆积密度来计算。一级粉煤灰 /cm3② 密度:粉煤灰的密度与它的颗粒形 .

粉煤灰也是分国标等级的: 一级粉煤灰 /cm3 ② 密度:粉煤灰的密度与它的颗粒形状、铁质含量有关,玻璃球含量多,粉煤灰密度大;氧化铁成分高,其密度亦大;含碳多的密度小;密度愈大 .

粉煤灰的密度是多少?粉煤灰的密度范围广泛,一般在至克/ 立方厘米之间。作为一种由燃煤电厂排放的固体废物,其形成源于煤燃烧产生的细灰。粉煤灰的主要氧化 .

2 天之前 · 我的钢铁网为您提供粉煤灰今日价格,粉煤灰价格多少钱一吨,粉煤灰报价表, 让您轻松了解粉煤灰市场价格动态,助您快人一步,掌握商机。 无锡 江阴 扬州 常州 镇江 盐城 南通 .

1、粉煤灰是在煤燃烧后的的烟气产生的细灰,它是燃煤电厂排出的首要固体废物。粉煤灰的首要氧化物组成为:二氧化硅、氧化铝、氧化铁、三氧化二铁、氧化钙、二氧化钛 .

一般来说,液态粉煤灰的设计容重范围在1500~1800kg/m³之间。这个范围是基于液态粉煤灰的制备过程中,将一定量的水泥、粉煤灰、水和外加剂进行拌和,形成具有一定流态的混合料,并 .

京台高速廊坊段桥涵台背(液态粉煤灰)施工作业指导书流态粉煤灰台背回填是河北省高速公路施工中推广的一项新材料和新工艺,它利用了流态粉煤灰自重轻、密实性.. 登录 .

需要注意的是,粉煤灰 的密度会受到很多因素的影响,如物理性质、颗粒大小、形状等。因此,在实际应用中需要根据具体的情况进行调整和确认。同时,施工过程中还需 .