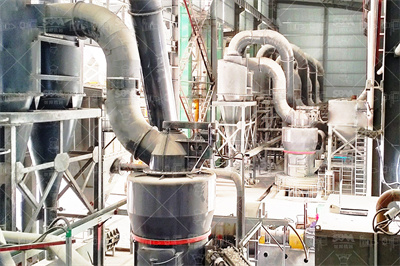

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

本发明实现上述构思的技术方案是清除海砂中的贝壳的方法,其特征在于包括以下步骤(1)分离开启流道管下方的水源,使流道管中水流从下往上流动,形成垂直上升 介质流,将粒径范围符合《建筑用砂》国家标准的贝壳与海砂的混合物注入流道管,用 ...

工作原理:在使用海砂碎贝分选机,首先利用片状贝壳和海砂在水中沉降速度的不同采用逆流反冲水逐级对海砂中的片状贝壳和粒度较小的海砂完成初级分选,初级分选后的 .

本发明提供一种清除海砂中贝壳的方法及使用该方法的分离装置,本发明将筛分和水力分级方法相结合,人为制造牛顿流体场,使分散相 (贝壳)和连续相 (海砂)之间发生相对 .

为了市场的需求,海砂淡化技术不断更新,发明了一系列去除海砂里面掺杂的氯、碱盐、贝壳等杂质的的分离设备。这些新器械、新方法改良了原海砂淡化工艺,使得更加高 .

海砂的除盐法分三个步骤: 1、海砂经振动分筛机分选,除去混入海砂中的超粒径颗粒以及贝壳等杂物。 2、用冲洗滑道和洗砂机进行次冲洗。 (见表3) 海砂中往往含有大量贝壳,贝壳对混凝土 .

本发明的目的在于克服上述缺陷,提供一种能够切实、高效地实现贝壳与海砂的分离的清除海砂中的贝壳的方法及利用该方法清除海砂中的贝壳的分离装置。

本发明提供一种清除海砂中贝壳的方法及使用该方法的分离装置,本发明将筛分和水力分级方法相结合,人为制造牛顿流体场,使分散相 (贝壳)和连续相 (海砂)之间发生相对运动,使两。 海砂贝壳筛 .

在我国沿海海砂处理实践中,一般采用筛网清除大于一定粒径的贝壳,这种办法有很大的局限性,在筛除大于设定粒径的贝壳时会同时筛除大于该粒径的海砂,并且无法清除小 .

经过反复试验,发现贝壳皮与海砂在牛顿流体中最终沉降速度各不相同,如何利用贝壳 皮与海砂在水流动场中的差异,实现贝壳皮与海砂分离的装置,有待解决。 发明内容 .

青州志伟环保(图)海砂清洗去贝壳深圳海砂清洗由青州志伟环保具体实验方法如下: 400g海砂用温度为(1055)干燥烘箱进行 烘干恒温,冷却——含泥量,%,精确到 %m,——试样总重,gm:——试样 .