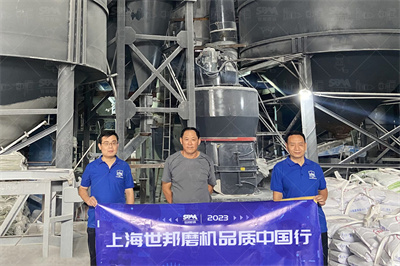

超细微粉磨粉机

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

目录![]() +86 180 3780 8511We Hava More 35 Years Of Expeiences

+86 180 3780 8511We Hava More 35 Years Of Expeiences

超细微粉磨粉机是一种细粉及超细粉的加工设备,此微粉磨主要适用于中、低硬度,湿度小于6%,莫氏硬度在9级以下的非易燃易爆的非金属物料。它是经过20多次的试验和改进,为超细粉的生产而研发制造的新型磨粉机,…

我们公司专业生产大、中型雷蒙磨粉机,拥有22年磨粉经验,科菲达已经成为中国领先的磨粉机制造商和供应商。 R系列雷蒙磨粉机是经过我们的专家优化升级改造,具有低损耗、投资小、环保、占地面积小等优点,它比传…

MTW系列欧式磨粉机是我公司新近推出具有国际先进技术水平,拥有多项自主专利技术产权的最新粉磨设备—MTW系列欧式磨粉机,以悬辊磨粉机9518为基础,采用欧洲先进制造技术,它能满足客户对产品粒度、性能可…

获得了CE和国家专利证书,超压梯形磨粉机享誉澳大利亚、美国、英国、西班牙等客户国家。该机型采用了梯形工作面、柔性连接、磨辊联动增压等五项磨机专利技术,开创了超压梯形磨粉机的世界最高水平。TGM系列超压…

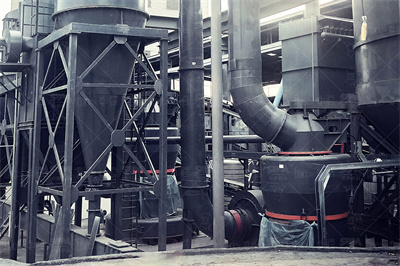

超细立式磨粉机是结合我们公司几年的磨机生产经验,它的设计和研究的基础上立磨技术,吸收了世界各地的超细粉碎理论的一种先进的轧机。本系列产品是一种专业设备,包括超细粉碎,分级和交付。 LUM系列超细立式…

立式磨粉机是一种大型磨粉机,专门为解决工业磨机产量低、耗能高等技术难题,吸收欧洲先进技术并结合我公司多年先进的磨粉机设计制造理念和市场需求,经过多年的潜心设计改进后的大型粉磨设备。立磨采用了合理可靠的…

由于此网站的设置,我们无法提供该页面的具体描述。

案例2:柘荣县乍洋乡水碓村民委员会与陈清华、刘宜达土地租赁合同纠纷二审民事判决书[福建省高级人民法院(2014)闽民终字第1292号]认为,"上诉人陈清华、刘宜达与被上诉人水碓村委会双方签订的《集体林地(使用地)租赁合同》明确约定水碓村委会以

在承包的土地上进行挖沙肯定是违反国家法律的规定,不仅不允许,很有可能被集体收回的开能,同时国土资源部门要进行处罚。 所以承包土地要合理利用,不的破坏,不要 .

由于此网站的设置,我们无法提供该页面的具体描述。

1、租场地倒卖沙子不合法。 私自开采沙石,是违法行为,因为开采行为会导致环境污染,建议去咨询政府部门,市场监督管理局、税务局等获得审批相应的许可文件。 2、法 .

您在查找租个场地堆沙石可以吗吗? 抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。 更有海量高清视频、相关直播、用户,满足您的在线观看需求。

承包村集体工业用地创办公司可以自建设厂房吗? 5 [转载]租赁农村集体土地建厂房拆迁时如何补偿? 23 租赁农村集体土地建厂房拆迁时如何补偿? 21 租赁农村集体土地来修建厂房,需要政府审批吗 32

4 天之前 · 个人农村土地卖沙子是否合法,主要取决于卖沙行为是否符合相关法律法规的规定。 一般情况下,单纯的卖沙行为并不违法,但如果沙子属于矿产资源,且未经许可擅自开采,则可 .

农村土地有分配到户的和没有分配的,分配到户的农民有对土地的合法使用权,可以进行转让租赁等,当然你租用来堆沙也是合法的! 已赞过 已踩过 你对这个回答的评价是?

租来的土地不可以挖土卖,因为买卖或以其他形式非法转让土地是违法的。土方开采和销售需遵守国家法律法规,并办理相关手续。同时,土地租赁合同也会规定土地的使用方式和限制条件,擅自挖土出售可能违反合同并导致法律纠纷。因此,利用土地资源进行商业活动前,应了解相关法律法规和 ...

非法挖掘取土有哪条法律依据和法律责任法律依据 《中华人民共和国土地管理法》第三十六条规定:非农业建设必须节约使用土地,可以利用荒地的,不得占用耕地;可以利用劣地的,不得占用好地。止占用耕地建窑、建坟或

由于此网站的设置,我们无法提供该页面的具体描述。

导读:租用土地建厂房需要经过住建部分的许可才具有合法性,否则属于违规,遇到这种情况是可以向国土资源部门举报的。土地租赁,土地租赁是某一土地的所有者所有权与土地使用者使用权在一定时期内相分离,土地使用者在使用土地期间向土地所有者支付租金,期满后,土地使用者归还土地的 ...

别人租我家土地堆料子几年不付租金也找不到人我把处理卖了行吗?最好不要自己私自处理,找不到对方人了先报警,警方态度一般认为经济纠纷的让你走法院,法院会让你去找人,找不到人和地址不会搭理你。基本这样流程,

农用地挖沙的行为如果有当事人和村集体双方签署的合同约定的话,一般不涉及违法,不过无证经营是违法的。如果该地块为严格控制的农保地,可以认定你的行为涉及非法 .

由于此网站的设置,我们无法提供该页面的具体描述。

具体可以详细说说吗?如果可以卖,我们老家还有很多土地都可以卖吗?现在空了的土地都可... 我家有块田,瓦厂需要泥巴,然后我就卖了50厘米下去。请问这样做违反了国家是什么规定没有。具体可以详细说说吗?如果可以卖,我们老家还有很多土地都可以卖

在不允许挖沙的地方挖沙,你帮助拉沙就是违法的。 是和挖沙的人一同违法。 法律分析违法占用耕地堆放沙石的,依法应由土地主管部门责令限期改正或者治理,可以并处罚 .

由于此网站的设置,我们无法提供该页面的具体描述。

11 小时之前 · 农村农业土地可以租赁,但需遵循相关法律法规。一、法律依据为《中华人民共和国土地管理法》第六十三条,允许经营性用途的集体经营性建设用地出租。二、具体规定包括签订书面合同、明确土地用途和租赁条件,需经村民会议三分之二以上同意。三、注意事项要求双方明确权利义务,出租方 ...

国有土地使用权的出租,更准确的是指建设用地使用权出租,属于土地二级或者三级市场。长期以来,我国法律只承认房屋租赁关系,禁止土地出租,1988 年《宪法修正案》不再禁止建设用地使用权出租,1988 年国务院颁布的《城镇国有土地使用权出让和转让暂行条例》进一步明确规定建设用地使用 ...

由于此网站的设置,我们无法提供该页面的具体描述。

村委会有权出租村里的集体土地吗?村委会可以出租土地。村民委员会是村集体的代表,可以依法发包本集体所有的土地。同时要区分以下情况进行处理:1、发包耕地的,只能向本村村民发包,不得向村外人员发包。2、发包荒

修路以后原生态的我一个石头都没动,那纯碎是我修路时没地方堆,所以我租地请车转运来堆起的,这种卖的话违法吗? 回答 赢了网好律师团队 这个不算违法的,但是你可以使用,但是不可以倒卖

根据《城市市容和环境卫生管理条例》第三十八条规定,任何单位和个人在城市建设用地、绿化用地、广场、公园、道路、河道、湖泊等公共场所,以及在居民区、工业区或 .

一、私自卖土多少方算违法1、当事人私自售卖土方的,不论数量多少均属于违法行为。非农业建设必须节约使用土地,可以利用荒地的,不得占用耕地;可以利用劣地的,不得占用好地。禁止占用耕地建窑、建坟或者擅自在耕...

农村的土地租给别人堆放河沙是否违法,需考虑以下要点:1、土地性质与用途:依据《中华人民共和国土地管理法》第六十三条,土地需被规划为工业、商业等经营性用途 .

您在查找租的土地能堆土吗吗?抖音综合搜索帮你找到更多相关视频、图文、直播内容,支持在线观看。更有海量高清视频、相关直播、用户,满足您的在线观看需求。

工地挖出的土方能卖吗工地挖出的土方不能随意出售。在我国,土地所有权归国家或集体所有,不允许私自买卖。根据《中华人民共和国土地管理法》,土地的所有权不得买卖、出租、抵押或以其他形式转让,所有权归谁是不可

在没有违法的土地上堆沙石是否违法,取决于土地用途是否改变及是否造成土地毁坏。1、改变土地用途的法律规定:根据《土地管理法》,非农业建设需节约用地,禁止占用耕地进行非农业活动。2、造成土地毁坏的法律规定:依据相关司法解释和《刑法》,非法占用耕地并造成毁坏可能构成犯罪。